February 17th, 2026

Manufacturing Spotlight: USAMR

Nick Saur and Shiva Sundaram, co-founders of USAMR, are determined to solve a growing challenge in the automation and mobile robotics market

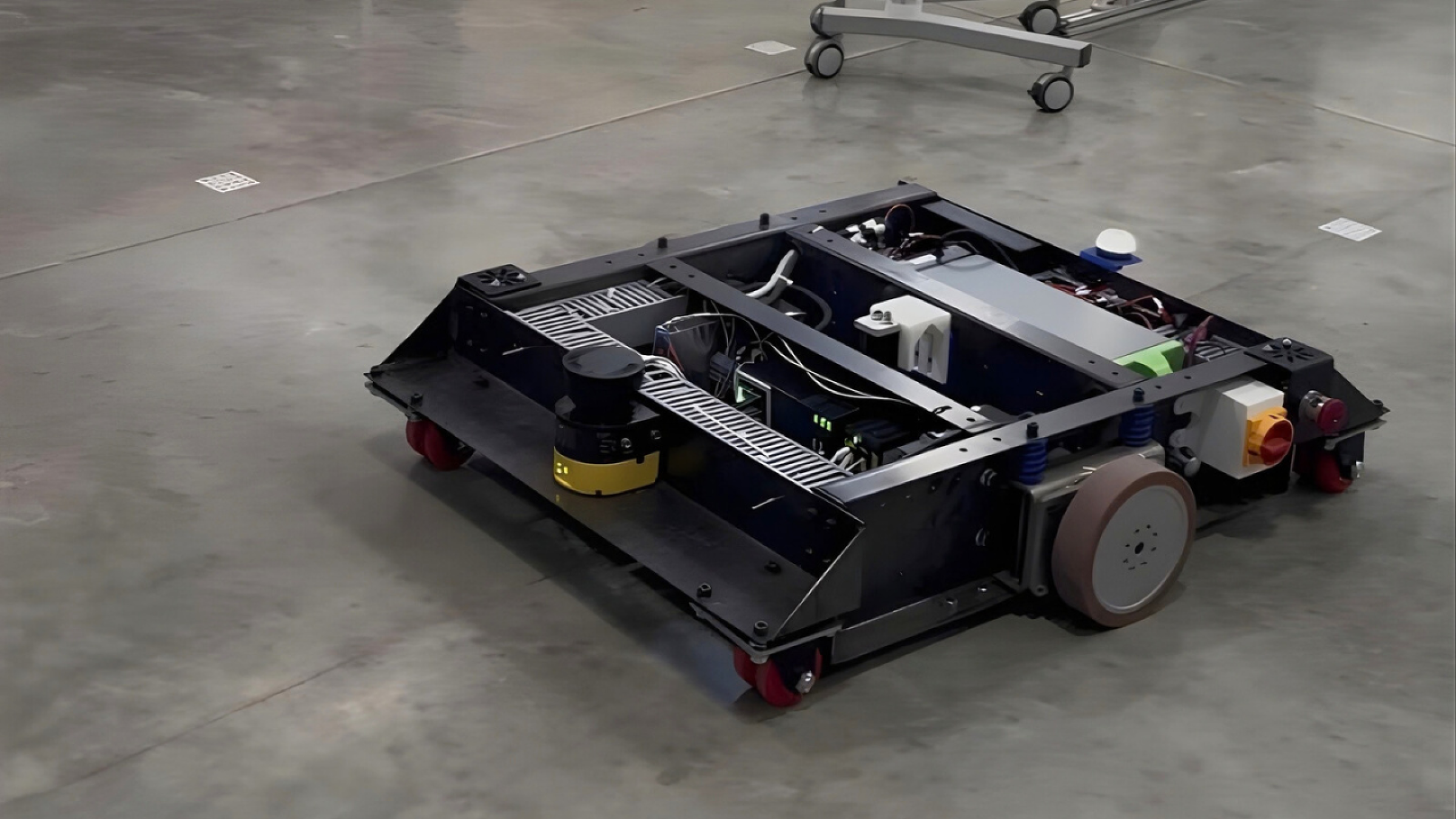

How USAMR Is Transforming Warehouse Automation

Nick Saur and Shiva Sundaram, co-founders of USAMR, are determined to solve a growing challenge in the automation and mobile robotics market. While many companies purchase robots manufactured overseas, there is often a disconnect between software developed in the United States and systems originally programmed in Europe or China. This mismatch can lead to costly inefficiencies and unrealized value.

“The return on investment was never realized at all,” Sundaram said when reflecting on mobile robot deployments with these international inconsistencies.

To bridge this gap, USAMR imagined a shelf-to-person solution designed to transform a traditional manual warehouse into a highly efficient, automated system that directly compares to a giant vending machine.

The Founders Driving Innovation at USAMR

Nick Saur is a Michigan native with a bachelor’s in mechanical engineering from Michigan Technological University. Saur was quite possibly born with a drive for innovating logistics. His lineage includes Charles Saur, a mechanical engineer at Rapistan before it became the company it is today, Dematic. Charles has his name on several patents, among them are industry staples such as the accumulator conveyor, diverting shoe sorters and the folding steel carousels commonly seen handling luggage in airports.

Additionally, his great uncle holds a patent on one of the first unit-load ASRS systems, a crane with a carriage capable of retrieving pallets from storage racks. All of these technologies remain relevant today.

“I saw where the industry was going, and with my family legacy, it kind of makes sense that I’m pursuing a new company that is revolutionizing material handling,” said Saur.

Shiva Sundaram has worked in manufacturing and automation both out of state and internationally, including in Connecticut and India. He earned his master’s degree in Connecticut and worked there until his visa expired, requiring him to return to India. While working in automation abroad, Sundaram quickly noticed an opportunity to start his own business and later connected with Nick.

With support from Global Detroit’s Global Entrepreneur in Residence (GEIR) program, Sundaram was matched with Grand Valley State University and brought on as a visiting faculty member through the university and the GEIR program. Working directly with students, Sundaram participated in senior design projects each year. One sponsored team successfully built a lift-and-rotate mechanism for USAMR’s robot, which performed exactly as instructed.

Michigan-Based Partners Supporting USAMR’s Growth

Resources and support are essential when establishing a new business. For USAMR, they have received and continue to receive strong support from several companies based in Greater Grand Rapids.

- Speedrackis a local leader in the material handling industry that helped mentor Nick and Shiva on business fundamentals while also assisting with technical elements.

- Twisthink is an organization made up of strategists, designers, engineers, and developers that support business development. Twisthink assisted with early business ideation and continues to support USAMR’s growth.

- DeWys Metal Solutions is a U.S.-based metal fabrication company that helped USAMR visualize its potential for scalability and sales pipeline growth. The team also showcased automation integration across its own operations and how USAMR can support them and other manufacturers with their technology solutions.

- Bosch Rexroth is a global leader in drive and control technologies that have helped with resources and will have critical controls components in USAMR’s production robots.

How USAMR Is Scaling Warehouse Automation Solutions

In many facilities, products are stored on racks, making order fulfillment a time-consuming process as employees are required to walk the floor to locate and retrieve items. With USAMR’s approach, robots will be able to retrieve entire racks and deliver them directly to workstations, allowing employees to quickly pick items and process orders while robots move on to the next task. By eliminating unnecessary travel time, this system increases efficiency and enables human workers to focus on higher-value work.

“West Michigan is the best place to start a business because everyone is so friendly and willing to help in really bizarre ways,” said Saur.

West Michigan’s ecosystem is unique. The companies here want to see each other succeed and are open to collaboration. Interested in getting involved? Reach out to us!

To be featured in a video series, contact Elise Rapeyko

Elise Rapeyko

Engagement Coordinator, MMTC-WestElise is the Engagement Coordinator for Michigan Manufacturing Technology Center-West, supporting the client proposals, relationships, events, and marketing efforts for the organization.

Full Bio

Elise Rapeyko

Engagement Coordinator, MMTC-WestElise is the Engagement Coordinator for Michigan Manufacturing Technology Center-West, supporting the client proposals, relationships, events, and marketing efforts for the organization.